Rebuilding Rhoan for Real-Time 3D

Rebuilt the Rhoan helmet model for real-time 3D, optimizing geometry, textures, and performance for interactive and immersive experiences.

-

Strategy

Product Visualization Strategy, Performance-Centric Modeling, Interactive Customization UX, File Optimization Strategy

-

Design

3D Model Design, Texture & UV Mapping, Web Optimization, Realistic Material Presentation, Interactive Product Design

-

Client

KAV

Background

Goal: Redesign the 3D product model for KAV’s new Rhoan helmet to deliver higher visual fidelity, reduced file size, and better performance across devices — all without compromising on product detail or realism.

The original model, created externally, served its purpose but introduced limitations in quality and flexibility:

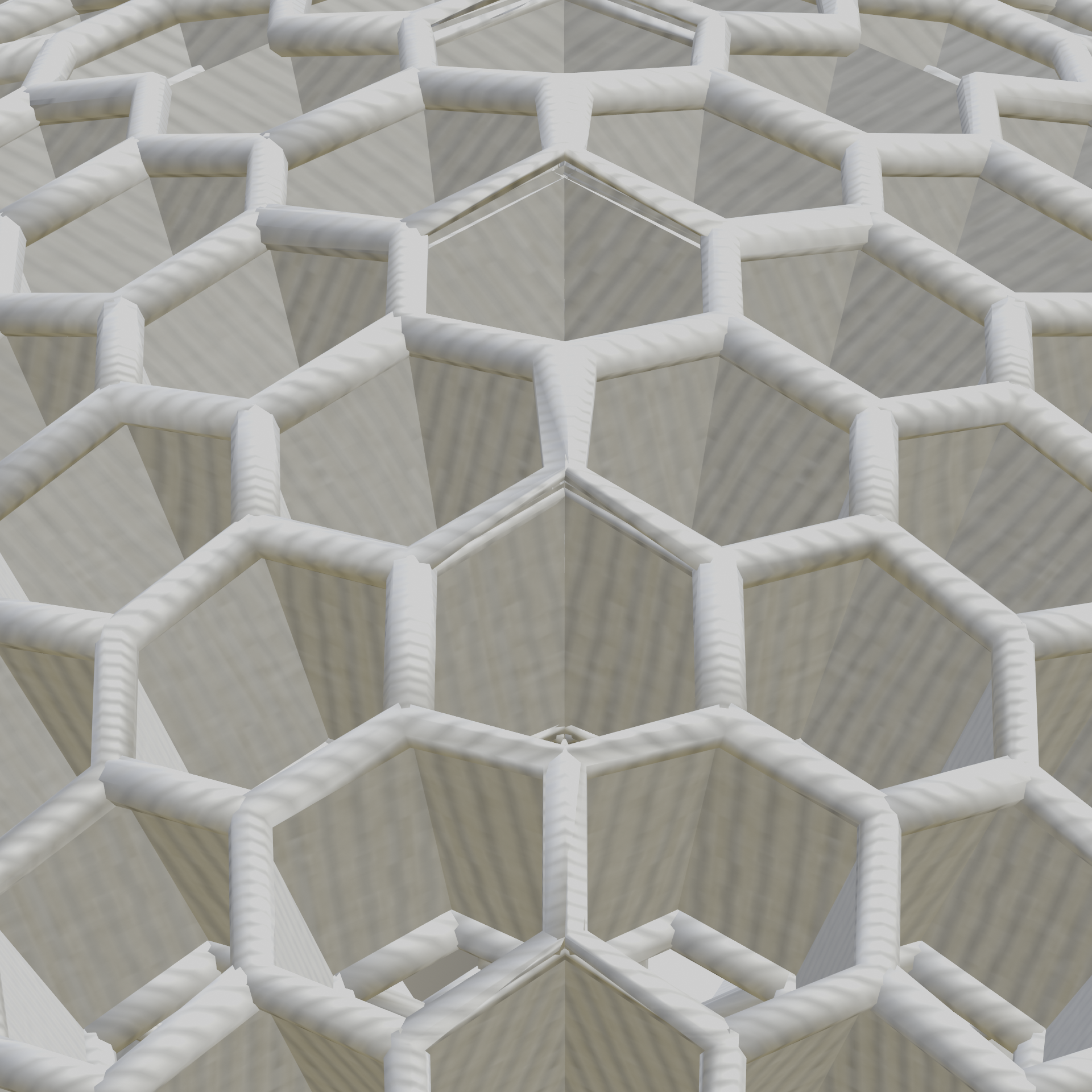

Inaccurate geometry for critical product features like hex structures.

Broken UVs and normal artifacts leading to texture and shading issues.

Pixelation due to limited texture resolution and mesh design.

Excess file size (7.78 MB) affecting performance and load time.

Layer lines mapped from incorrect print orientations, reducing realism.

This project aimed to address these issues with a refined, handcrafted approach — resulting in a smaller, smarter, and more realistic model that better represents the Rhoan’s production-ready design.

Initial Vendor Mesh (7.78MB)

Refined Custom Build (5.46MB)

Acknowledging Limitations

When KAV prepared to launch the Rhoan helmet, the goal wasn’t just to release a new product—it was a chance to raise the bar for the digital experience. Rather than replicate the workflow of past models, we treated this as an opportunity to address earlier limitations and explore what was truly possible within the Angle3D platform.

The original Nova model, created externally from CAD, functioned as a first step. At 7.78 MB, it met baseline visualization needs, but it came at a cost—excess geometry, inconsistent UVs, and under-optimized rendering that slowed performance and reduced realism.

Key product details like the hex structure and 3D-printed layer lines were approximated using geometry-heavy workarounds, which compromised UV integrity and introduced visual seams, broken shading, and material distortion in the configurator.

With the Rhoan model, we shifted our approach. Rather than accept the limitations of the platform, we engineered against them—prioritizing mesh clarity, UV intent, and lightweight textures. Where native features like multi-UV support were absent, we implemented masked overlays and clever geometry duplication to simulate complex effects without bloating the file size.

This wasn’t just about building a lighter model. It was about demonstrating that thoughtful design, platform fluency, and an attention to detail can unlock a result that feels sharper, faster, and more real—despite technical constraints.

Hex Structure: From Illusion to Integrity

In the original Nova model, the hex structure was built using layered geometry—flat planes and curved shapes stitched together to suggest a lattice. This approach led to broken UV seams, mismatched normals, and visual artifacts that disrupted material rendering in the configurator.

For Rhoan, the entire hex structure was rebuilt from the ground up. Walls were modeled with a focus on mesh continuity and UV efficiency. Each surface was uniquely unwrapped to support clean normal map projection, enabling realistic lighting and shading without increasing vertex density.

The result is a crisper, more convincing digital representation of the helmet’s internal lattice—one that preserves fidelity across devices and aligns visually with the real-world product.

Rethinking UVs: Turning Constraints Into Craft

One of the most critical upgrades in the Rhoan model came from reimagining how UVs were structured. While often an invisible layer of a 3D asset, UV mapping proved essential in unlocking fidelity, consistency, and performance.

The original Nova model used a rushed, fragmented UV layout. Key areas were compressed, padding was inconsistent, and a single-projection method limited how well we could depict real-world features like layer lines or shell transitions. Texture stretching, pixelation, and loss of visual clarity were common.

For Rhoan, we rebuilt the UVs from scratch—segmenting the helmet into logical zones based on visual priority. High-fidelity regions like the hex and shell were given generous UV space, while lower-impact areas were scaled accordingly. This allowed us to maintain texture sharpness even within the limits of a single 1K texture map.

We also introduced a multi-UV logic internally, separating physical form from visual detail. One channel focused on geometry-based features like curvature and shading, while the other aligned precisely with the 3D-printed layer orientation, preserving the real-world look and feel of additive manufacturing.

Even though Angle3D didn’t support multi-UV GLB exports, our UV-first approach gave us room to adapt. Using mirrored meshes and masked duplicates, we recreated the desired result through smart layering—delivering a highly detailed visual outcome that remained lean and scalable.

Asset Optimizations

File Size

Resolution

Footprint

More Detail

Faster Load

Conclusion & Reflection

The Rhoan helmet model represents more than an incremental improvement—it’s a case study in how constraint can drive creativity. Faced with platform limitations, legacy workflows, and performance trade-offs, we took the time to rethink, restructure, and refine.

Where the Nova model prioritized speed, the Rhoan model prioritized fidelity. From rebuilding the hex structure to reengineering UVs and implementing layered detail techniques, we delivered an experience that was lighter in weight, higher in quality, and better aligned with the product’s real-world identity.

The limitations of the Angle3D platform didn’t restrict us—they challenged us. And in that challenge, we found new ways to simulate detail, improve clarity, and streamline performance without compromise.

In the end, this project proved that precision, intent, and care lead to better outcomes than speed alone. The result is a digital model that doesn’t just function—it performs, impresses, and accurately represents the innovation behind the Rhoan helmet.